GreenSwitch® turns manure into sustainable Nitrate fertilizer

Van Iperen International is proud to announce a groundbreaking concept, called GreenSwitch®. Within the concept, manure is turned into a readily available Nitrate fertilizer suitable for fertigation whilst producing biogas. GreenSwitch® is based on a circular patented production process with a minimized Carbon footprint.

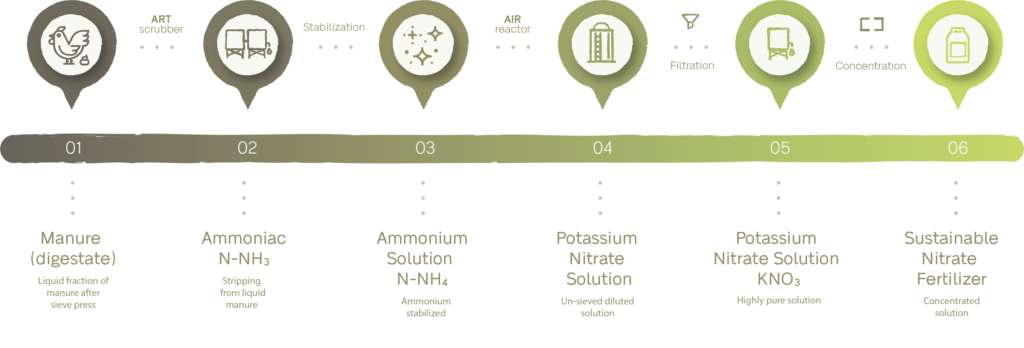

How it works

Biogas installations are fueled by manure. The yearly input of a typical biogas installation is 200 kiloton of manure. During fermentation, 5 to 10% of the biomass is converted into biogas. In the remaining digestate, Nitrogen is available as Ammonium. The GreenSwitch® process converts the Ammonium from the residual product into valuable organic1 Nitrate, with a Potassium Nitrate solution as the final product. Ammonium from other manure processing operations can also be used.

A string of benefits

GreenSwitch® has substantial benefits. The end product is a pure transparent liquid solution, ideal for fertigation without risk of clogging of the irrigation system. Currently, GreenSwitch® is the only organic liquid fertilizer based on Nitrate on the market. Nitrate (N-NO3) is the most effective form for fertigation in conventional agriculture and now made possible in organic farming1. Therefore the products can be used both in conventional and organic1 farming, which in itself is a revolutionary development. Also, GreenSwitch® products can be produced close to the market, with turnkey scalable installations. Thanks to the low carbon footprint, GreenSwitch® products are unique from the sustainability point of view.

Project partners

GreenSwitch® is based on sophisticated technology, produced and patented by research & development company Pure Green Agriculture (USA). The first industrial size GreenSwitch® projects will be built together with our partners Agro Energie Hardenberg and Ferm O Feed. The first industrial-scale installations will be up and running in the first half of 2020. GreenSwitch® will produce the first organic fertilizer as of summer 2020.

This project was made possible by the Dutch Ministry of Economic Affairs and Climate Policy.